Oil & gas and energy

WORLD-CLASS SOLUTIONS FOR DEMANDING APPLICATIONS

Explore our products

Markets

Efficient, safe and environmentally sound

Demands on the oil and gas industry are increasing. Operational reliability, cost containment, safety standards and environmental protection are major considerations. GEA’s wide range of solutions not only meet our customers’ precise process-critical requirements, but they also comply with the most stringent safety and environmental standards while contributing considerably to reducing operating costs.

Our centrifuges clean all kinds of liquids — from crude oil to meet refineries’ specifications; to drain, bilge and produced water to help protect the maritime ecosystem.

Our process refrigeration and gas compression expertise is applied in many applications, including mixed- hydrocarbon compression, custom process cooling, boil- off gas & storage, cryogenic gas processing and LNG production.

GEA ATEX compressors for air conditioning help to keep heads cool in explosion-risk areas, by providing the right temperature for workers, facilities and supply.

GEA’s multi-stage steam ejector units for downstream processes in refineries exhibit low steam consumption, thus keeping the vacuum in the distillation column operating reliably and effectively.

Ready to address your challenges

Whether delivering complete, large-scale, highly engineered process refrigeration and gas compression solutions or proven equipment for a specific operating function — including compressor packages, chilling systems, centrifuges, A/C compressors or steam ejector units — GEA stands ready to meet our customers’ process-critical requirements in the oil & gas space.

Products & technologies

Centrifugal Separator

GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating…

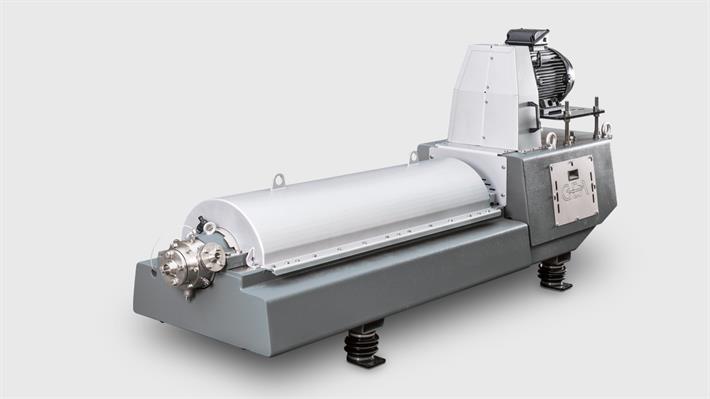

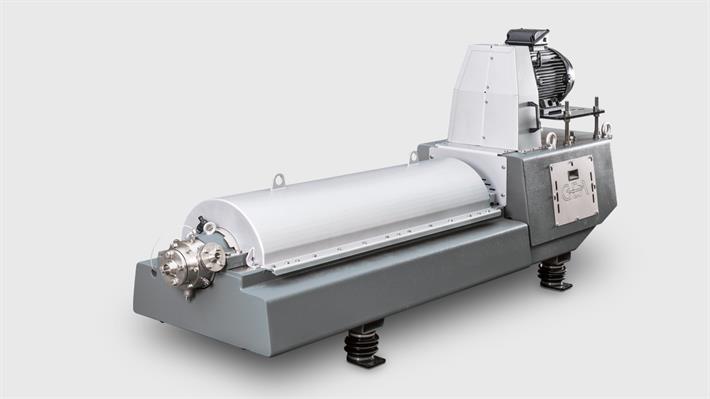

Decanter Centrifuge

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a…

Distillation Equipment

Distillation technology is used throughout the chemical, pharmaceutical, food and beverage and environmental technology industries.

Ejector Systems

Ejectors, are devices for the conveyance, compression or mixing of gases, vapors, liquids or solids in which a gaseous or liquid medium serves as the motive force. They are “pumps without moving parts”.

Centrifugal Separator

GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating…

Decanter Centrifuge

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a…

Distillation Equipment

Distillation technology is used throughout the chemical, pharmaceutical, food and beverage and environmental technology industries.

Ejector Systems

Ejectors, are devices for the conveyance, compression or mixing of gases, vapors, liquids or solids in which a gaseous or liquid medium serves as the motive force. They are “pumps without moving parts”.

Oil & gas and energy

GEA Crude Oil Treatment Systems

With the Crude Oil Treatment System, GEA has designed a flexible but easy-to-integrate solution for the continuous treatment of crude oil in various process setups in upstream and downstream processes.

GEA Insights

Story

The circularity imperative in manufacturing

Story

Just water please – clean water

Customer case

Saudi Aramco puts GEA centrifuges to the test