Storage Tanks

STORAGE TANKS

Alfatech’s storaging applications for liquid materials with different size and efficient storaging designs for our customer to have perfect result.

Explore our products

Products

Types of storage tanks

- Atmospheric: Atmospheric storage tanks is a container of liquid contained at atmospheric pressure in it. The main design codes for welded atmospheric tanks are API 650 and API 620. API 653 is used for the analysis of in-service storage tanks.

- High Pressure: It must be made to withstand pressures such as a liquefied gas such as hydrogen or chlorine, or compressed natural gas. These tanks can be called cylinders, and since they are pressure vessels, they are sometimes excluded from the class of “tanks”.

- Thermal Storage Tanks: For seasonal heat energy storage, large insulated and shielded water tanks are used to store the thermal heat of the sun throughout the year. Related technology has become widespread in district heating systems, especially in Denmark. Ice and slush tanks are used for short-term colds for air conditioning, allowing refrigeration equipment to work at night, when electric power is cheaper.

- Milk Tank: A bulk milk cooling tank in dairy farming is a large storage tank for cooling and keeping milk at a cold temperature until it is received by a milk carrier. Since milk is separated from the breast at about 35 ° C and retains its natural resistance to bacteria after extraction, milk tanks are used for rapid cooling to a storage temperature of about 4 °C to 6 ° C, preventing further growth of microorganisms. It is usually made of stainless steel and is used to store raw milk on the farm in good condition every day.

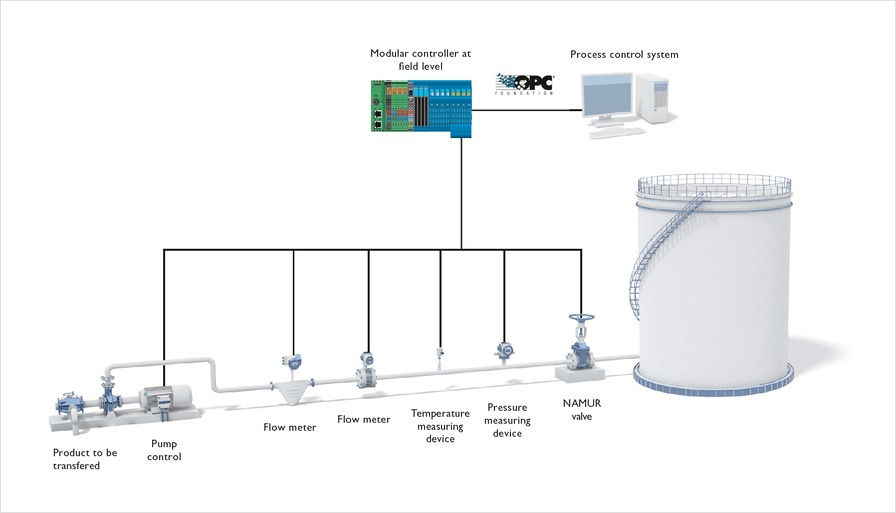

- Oil Storage Tank: The process of transferring oils is provided by means of wall pumps or stainless valves. Weighing groups are placed on the foot parts of the boiler. These systems, which determine the product’s amount, provide users convenience.

Storage Tanks Building Materials

Steel and concrete remain one of the most popular options for tanks, while glass-reinforced plastic, thermoplastic and polyethylene tanks are growing in popularity. They offer lower construction costs and higher chemical resistance, especially for the storage of special chemicals. Several relevant standards give recommendations on wall thickness, quality control procedures, and tests for various controllers.