Conveyor Systems

Conveyor Systems

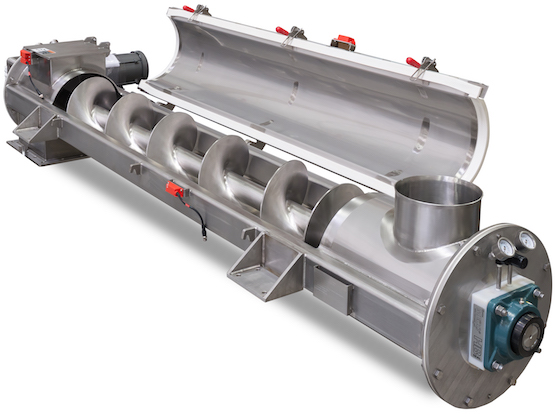

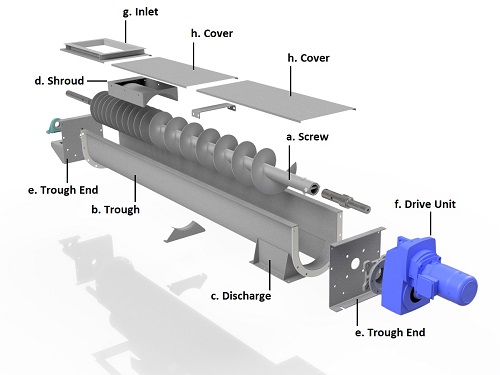

Alfatech engineering produces high quality and efficient conveyors with different designs that meet the needs of different industrial processes. Screw conveyors or screw conveyors are widely used in chemical, food, petrochemical, pharmaceutical and many industries.

Explore our products

Products

Conveyor Systems

Alfatech engineering produces high quality and efficient conveyors with different designs that meet the needs of different industrial processes. Screw conveyors or screw conveyors are widely used in chemical, food, petrochemical, pharmaceutical and many industries. Screw conveyors or screw conveyors are industrial equipment used to move large quantities of granular solids (e.g. powder, grains, granules), semi-solids, liquids and even non-flowable materials from one point to another. They support high operational efficiency by eliminating the need for workers to manually move around loads. It provides the advantage of safe and efficient product loading by eliminating labor force and possible work accidents.

Advantages;

Screw conveyors are capable of handling a wide range of bulk materials, from slow to free-flowing. Screw conveyors may have multiple entry and exit points. Bulk materials can be transported and distributed to various locations as needed. Slide gates or valves can be added to control the flow into and out of the screw conveyor.

When a screw conveyor is used as a measuring device, a screw feeder can be used. Screw conveyors are very compact and can be adapted to tight locations. Screw conveyors can be used to mix various products together and break up large lumps. Screw conveyors can be used to cool, heat or dry products in transit.

A chemical reactor is a process equipment where in chemicals are fed in order to make them chemically react with each other for the purpose of making a desired product. Chemical reactors are designed in such a way to increase the net present value for a given reaction and it is done by ensuring highest efficiency to output the desired product. There are distinct types of reactors intended to face extremely varied operating conditions, both in terms of the nature of the chemical species involved (reactants and products of the reaction) and of the physical conditions under which they operate. Chemical reactor needs to be able to carry out at least three functions: provide the necessary residence time for the reactants to complete the chemical reaction, provide the necessary heat exchange, place the phases into intimate contact to facilitate the reaction.

Design and manufacture according to international standards

High quality and long life guarantee

AISI 304, 316, 316L quality and certified stainless steel material

Jakets or half-pipe cails on the outside body, heating and cooling with coiled coil on the inside

-1,6 bar pressure and 300^C temperature resistance

Precise weighing with loadcell

Sealing with soft seal or mechanical seal

Gear unit drive IP56 (Exproof) motor

Product-specific mixing blades, wave breaking

Reactor Properties

- Design and manufacture according to international standards such as EN13455, API

- High quality and long life guarantee

- AISI 304, 316, 316L quality and certified stainless steel material

- Jakets or half-pipe cails on the outside body, heating and cooling with coiled coil on the inside

- -1,6 bar pressure and 300^C temperature resistance

- Precise weighing with loadcell

- Sealing with soft seal or mechanical seal

- Gear unit drive IP56 (Exproof) motor

- Product-specific mixing blades, wave breaking

Downloads

Conveyor Systems

Alfatech engineering produces high quality and efficient conveyors with different designs that meet the needs of different industrial processes. Screw conveyors or screw conveyors are widely used in chemical, food, petrochemical, pharmaceutical and many industries.

Screw conveyors or screw conveyors are industrial equipment used to move large quantities of granular solids (e.g. powder, grains, granules), semi-solids, liquids and even non-flowable materials from one point to another. They support high operational efficiency by eliminating the need for workers to manually move around loads. It provides the advantage of safe and efficient product loading by eliminating labor force and possible work accidents.

Advantages;

– Screw conveyors are capable of handling a wide range of bulk materials, from slow to free flow.

– Screw conveyors may have multiple entry and exit points.

– Bulk materials can be transported and distributed to various locations as needed. Slide gates or valves can be added to control the flow into and out of the screw conveyor.

– When a screw conveyor is used as a measuring device, a screw feeder can be used.

– Screw conveyors are very compact and can be adapted to tight locations.

– Screw conveyors can be used to mix various products together and break up large lumps.

– Screw conveyors can be used to cool, heat or dry products in transit.