Steel Construction

Steel Construction

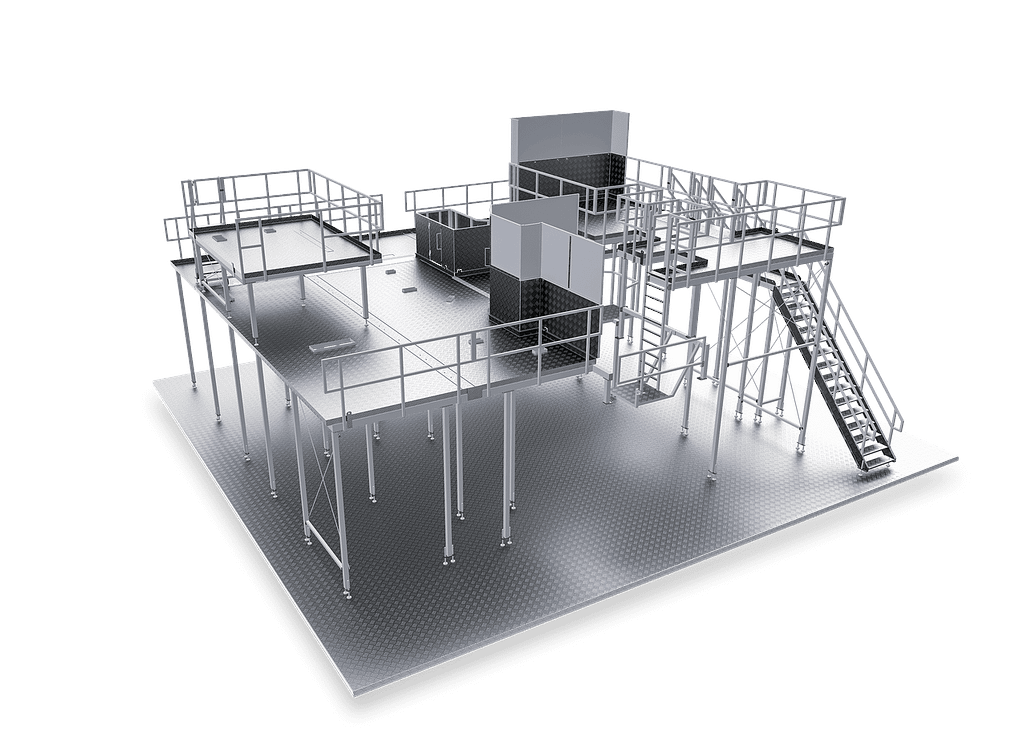

Alfatech Engineering produces useful, safe steel & stainless steel machine platforms with quality and durable design as engineering solutions for the business world.

Steel platforms are widely used in modern industrial production, petrochemical, chemical, food, pharmaceutical and many industries. The steel platform provides safe working space for industrial production activities and meets harsh field conditions.

Explore our products

Products

Steel Construction

Alfatech Engineering produces useful, safe steel & stainless steel machine platforms with quality and durable design as engineering solutions for the business world.

Steel platforms are widely used in modern industrial production, petrochemical, chemical, food, pharmaceutical and many industries. The steel platform provides safe working space for industrial production activities and meets harsh field conditions.

The expansion of modern industrial production scale and increasing efficiency has created higher requirements for the structural form and use function of the steel platform. At the same time, the requirements for the structural design of the steel platform are also increasing. Therefore, Alfatech Engineering constantly improves the design level of the steel platform and increases the performance of the steel platform.

Rust and corrosion caused by the external environment will reduce the safety performance and performance of the steel structure work platform to varying degrees. When designing the steel platform structure, attention should be paid to the anti-corrosion and anti-corrosion design of each component.

A chemical reactor is a process equipment where in chemicals are fed in order to make them chemically react with each other for the purpose of making a desired product. Chemical reactors are designed in such a way to increase the net present value for a given reaction and it is done by ensuring highest efficiency to output the desired product. There are distinct types of reactors intended to face extremely varied operating conditions, both in terms of the nature of the chemical species involved (reactants and products of the reaction) and of the physical conditions under which they operate. Chemical reactor needs to be able to carry out at least three functions: provide the necessary residence time for the reactants to complete the chemical reaction, provide the necessary heat exchange, place the phases into intimate contact to facilitate the reaction.

Design and manufacture according to international standards

High quality and long life guarantee

AISI 304, 316, 316L quality and certified stainless steel material

Jakets or half-pipe cails on the outside body, heating and cooling with coiled coil on the inside

-1,6 bar pressure and 300^C temperature resistance

Precise weighing with loadcell

Sealing with soft seal or mechanical seal

Gear unit drive IP56 (Exproof) motor

Product-specific mixing blades, wave breaking

Reactor Properties

- Design and manufacture according to international standards such as EN13455, API

- High quality and long life guarantee

- AISI 304, 316, 316L quality and certified stainless steel material

- Jakets or half-pipe cails on the outside body, heating and cooling with coiled coil on the inside

- -1,6 bar pressure and 300^C temperature resistance

- Precise weighing with loadcell

- Sealing with soft seal or mechanical seal

- Gear unit drive IP56 (Exproof) motor

- Product-specific mixing blades, wave breaking

Downloads